BE PREPARED: PROTECTING YOUR EQUIPMENT IN WINTER SEASON

Posted on 03/08/21 in: Technical Knowledge | | Oil & Gas | Mining | Author: Bill Liegman

A NECESSARY STEP TO LUBRICATION IN COLD WEATHER

The lessons we acquire as we grow and as we learn often provide us with the knowledge we end up using in multiple aspects of our life. One of the most valuable lessons is that of Preparedness. Probably the most widely known conveyance of that is attributed to the Boy Scouts of America. It became their motto at its inception in 1910. BE PREPARED.

Amy Lutz / shutterstock.com

And we are all familiar with the customary announcements and declarations that come during the seasonal changes in weather… “Wear Sunscreen!”, “Hydrate!”, “Take a Raincoat!”, “Check Your Car’s Anti-Freeze!”, “Dress in Layers!”, etc. All are forms of preparedness to enable us to avoid complications and hazards.

When it comes to keeping your equipment healthy that same type of preparedness is necessary to reduce the cold weather pitfalls that can deter you from achieving Optimal Lubrication on your equipment. There are multiple steps that companies and operators take to combat these cold-weather difficulties and they vary based on the operation, the lubricants in use, and of course the extremity of the cold.

It begins with awareness of the conditions and of the forecasting of conditions. In critical operations, the significance of being able to continue their production dictates extensive planning to prepare for cold weather. Not operating impacts revenue generation, sometimes in the thousands, and hundreds of thousands of dollars.

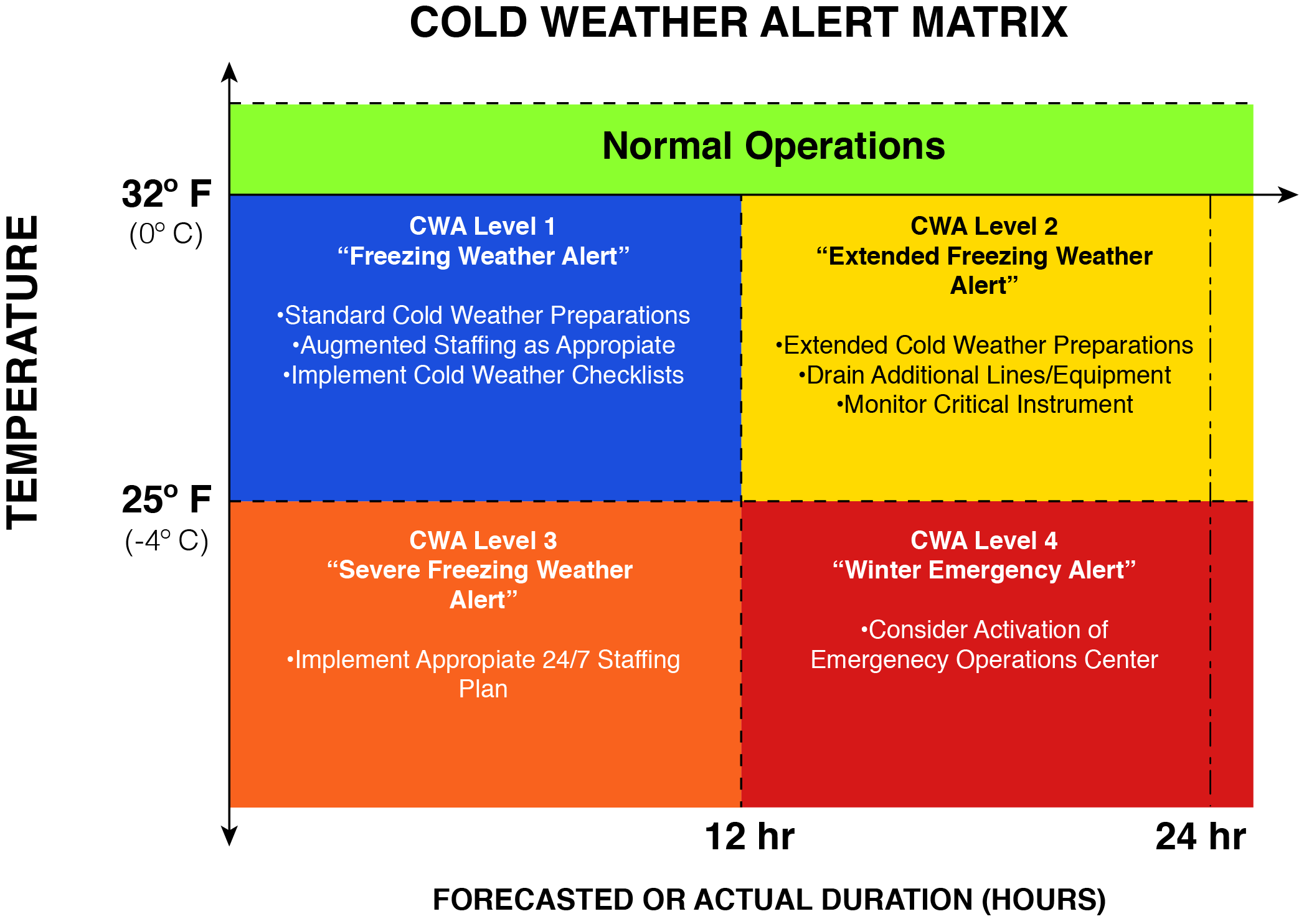

As an example, processes are put in place based on temperature expectations and conditions.

The interpretation of what would be viewed as a Cold Weather Alert is and will be dependent on the operation and the location. In the example above 32° F (0° C) is the trigger for Cold Weather. This would certainly differ in a northern climate that experiences temperatures well below zero.

So, with that variability in mind there will also be Preparations involved regarding the operation of equipment and the lubricants, fluids, and systems involved. In the case of a mining operation that involves the movement of many pieces of equipment including draglines, haul trucks, end dumps, loaders, conveyors, crushers, etc., here are some of the preparations and processes that may take place:

- Verify space heaters are available and working.

- Increase the drain frequency of air compressors to avoid freezing.

- Ensure supply of diesel and gas additives for cold weather.

- Wrap pipes at facilities with insulation.

- Drain water tanks and lines not in service.

- Park equipment inside shop bays if possible.

- Consider keeping equipment running continuously and initiate a “Hot Seat” change out procedure.

What about the lubricants and lubrication systems servicing the equipment?

Lubrication products in many cases are designed and formulated with the environmental conditions as a prerequisite to their characteristics and properties.

Greases are made in different NLGI grades to accommodate lower temperature conditions, like automobile engine oil, gear oils may be chosen with decreased viscosities to handle lower temperature conditions. In Southern climates a product like the Whitmore Caliber 3M grease may handle any seasonal changes as it will work well in temperatures down to -20° F (-29° C), depending on the grade chosen.

In Northern climates a product like the Whitmore Legacy M grease may be the option as it can be used in temperatures down to -35° F (-37° C). A Jet-Lube product like the NCS-30® Arctic thread compound can be used on drilling applications down to -40° F (-40° C) and in industrial anti-seize applications down to -65° F (-54° C).

The choice of lubrication system design and type may also be a consideration based on the environmental conditions that the equipment may be operating in.

A FARVAL lubrication system uses hydraulic movement to direct pistons to dispense the lubricant and typically can handle heavier greases in colder weather. The LINCOLN injector systems depend on a product venting to allow for the injectors to reload with lubricant and be ready for the next lube cycle.

What happens when cold weather hits and you have difficulties with a product or a lubrication system?

Here are some of the steps that are taken to prevent and resolve issues with the cold weather.

Lubricant containers or tanks are insulated or heated using heat blankets, heat bands or space heaters around them. Piping of the lubricant may be wrapped and insulated or traced with heat tape.

Many gearing applications are designed with case heaters that will warm the gear oil within them. They are turned on at an appropriate time to prepare for expected cold weather. Circulation pumps are kept running even during idle times of the machine or gearbox to keep the oil circulating.

If the equipment is shut-down for periods of time during the evening until normal operations begin again in the morning start-up procedures may include:

- Warming up the equipment for a period before any movement begins.

- Allowing the oils to circulate before the operating loads begins.

- Exercise the equipment [under no-load] to engage and stimulate the lubricant that is in service.

- Raise and lower the stick, rotate or round-house the machine, etc.

- Cycle the lubrication systems manually so that the grease that was idle during the night begins to move.

- In many cases this may involve manually cycling the lubrication system several times, as on the remote application points – like those at the boom point, there may be pressure switches that will not be satisfied.

- In cases where there are no end-of-line pressure switches, it is customary to visually look at the injectors or dispensing devices to see that they are distributing grease.

- Some end-users have their machine set-up with both a Summer grade product and a Winter grade product. They switch over to the Winter grade product prior to the expected start of the cold season, in enough time to allow the Winter product to fill the supply lines and be at the application point for when that cold-weather comes. That entire process is Preparation in itself.

- It is not as simple as looking at the forecast and determining that cold weather will arrive tomorrow, so let’s get a drum of Winter product underneath the system or let’s get the Winter product tank connected to the system.

- The timing of a grade change can be estimated by considering the usage rate of lubricant on a machine. The correct seasonal lubricant change includes displacing lubricant already in the systems supply line circuits. With this in mind, we must consider that some Dragline Auto-Lube Supply Line Circuits can be more than 2” x 400’ or approx. 15,000 cu in or >500 lbs. in capacity. Therefore, one must calculate how long (weeks/months) it will take to displace the lubricant already within the supply line before seasonal temperatures start to change dramatically.

- For example, a large Dragline (1500 to 8000 series machines) the EPG Consumption Rate is approximately 2 lbs. Per operating hour, therefore, it would take a machine operating 20 hours per day (avg.) using 40 lbs. per day, at least 15 days of normal operation to purge the supply line with new lubricant grade. We also must consider the product in the feed lines and bearings, and bushings. Roughly speaking, we should begin making grade changes within 20-30 days prior to when consistent cold temperatures are expected.

- For machines that do not operate on a consistent schedule, it makes calculating time to change grades more difficult. In this event we have 2 choices; that is to use a lighter or heavier grade year-round. If one chooses to use a lighter grade year-round, then lube cycle frequencies may need to be accelerated during the Summer months to maintain adequate lubrication of equipment. If one chooses to use a heavier grade year round then it may be necessary to adjust the production schedule to when conditions are favorable to allow the Auto-Lube Systems to function properly.

- Whitmore recommends avoiding the use of a too light or thin product. If the product is too thin during warm periods the lubricant may not withstand the loads of bearings, and in particular bushings and open gears. Rather it is better to lean towards the heavier grade selection. If low temperatures start causing the systems to go into fault then there are some steps that can be implemented to ensure the systems are working properly and eliminate the faults. These steps include making adjustments to air and lube pressure, and perhaps additional adjustments to the cycle and alarm timer settings.

- One last consideration, most Dragline and Shovel bearings and bushings require replenishment every 250 operating hours, so it is not the end of operation if several lube cycles are missed. In the case of open gears, they do require consistent relubrication every few hours of operation maximum (preferably more frequently,) but here the gears could be lubed manually using a 5 gal bucket sprayer and proper grade product.

There are products on the market like the Whitmore All-Season Open Gear products that has worked well in temperature ranges from - 30° F (-34° C) to 100° F (38° C). Use of this type product virtually eliminates the seasonal product issue, but it too should also be monitored.

Jet-Lube has pipe thread lubricants for the Oil & Gas industry that can be applied in weather as cold as 40° F (-40° C). Anti-Seize lubricants down to -65° F (-54° C).

The lubrication process begins with the selection of The Right Lubricant… It does not end until that lubricant reaches its destination. Whitmore | Jet-Lube has been providing lubricants and specialty products globally for decades. From Siberia to the Yukon we understand what it takes to lubricate equipment in cold weather.

So, remember the Scout motto… Be Prepared.

It’s Cold Outside.