Crushed Aggregate Plant Reduces Downtime Using Deacon Crush-Bac™

Posted on 10/22/21 in: Testimonials & Case Studies | Mining | Author: Diego Serna, Patrick Passe, Steve Spiegel

Company

One of the largest producers of crushed stone, sand and gravel in the U.S. With its robust network of plants and ability to transport materials by water and rail, our client has the capability to supply construction projects in major markets across the country and operates ready mixed concrete and asphalt facilities in select markets across the U.S. and Canada.

Challenge

Copps Backing Compound must sit overnight (8-12 hours) once poured and when removed during a wear liner changeout is found to be cracked or significantly deteriorated. This increases down time and ultimately shortens the operational life of the machine as a result of inadequate protection from harsh vibration / friction.

Solution

DEACON Crush-Bac vs. Copps Backing Compound

Faster return to service, unsurpassed tensile strength, 77% more volume per kit

Product Recommendation

DEACON Crush-Bac

Epoxy Backing Compound

- 77% more volume than competitors

- Fast functional cure

- High compression strength

- Superior tensile strength

- Low odor

- Minimal shrinkage

- Reduces vibration / friction

- Dampens noise

- Eliminates voids

- Smooths alignment errors

- Maximizes equipment efficiency

- Prolongs operational life

Results

• Crusher back in service 5 hours after last kit was poured (instead of 12 hours)

• 19 kits required to fill crusher compared to 33 kits of Copps (42% less)

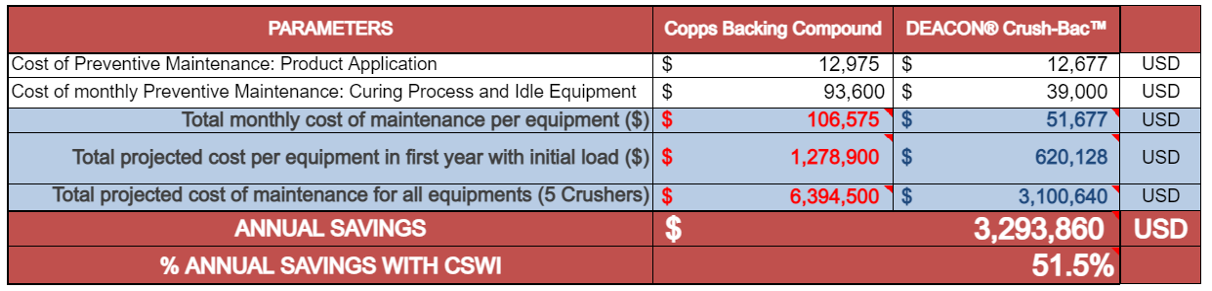

• 51.5% overall annual cost savings from using DEACON Crush-Bac

Equipment and Application

Poured into bowl liner and mantle of 1998 Svedala Cone Crusher (H-6000-FB-EC2/MF-44/48/50/40-2)

COPPS Backing Compound

Stress fractures and significant deterioration after 400 hours in operation

DEACON Crush-Bac

Removed intact and fully bonded to bowl liner after 550 hours in operation

Result Analysis