Horizontal Directional Drilling (HDD) Overview & Jet-Lube's HDD Product Line

Posted on 12/10/20 in: Product Knowledge | Horizontal Directional Drilling | Author: Don Howard - OEM and Strategic Project Manager

Horizontal Directional Drilling, a.k.a. HDD or directional boring, is a trenchless, underground conduit and pipe installation method. HDD can be used to install utilities in urban, metropolitan and industrial areas, environmentally sensitive areas and other obstructions with minimal surface disruption.

The “directional” component of horizontal directional drilling is that the method permits the operator to 'steer' the drill head in any direction to avoid obstructions while placing conduits or pipes along a desired path.

Horizontal Directional Drilling Operation:

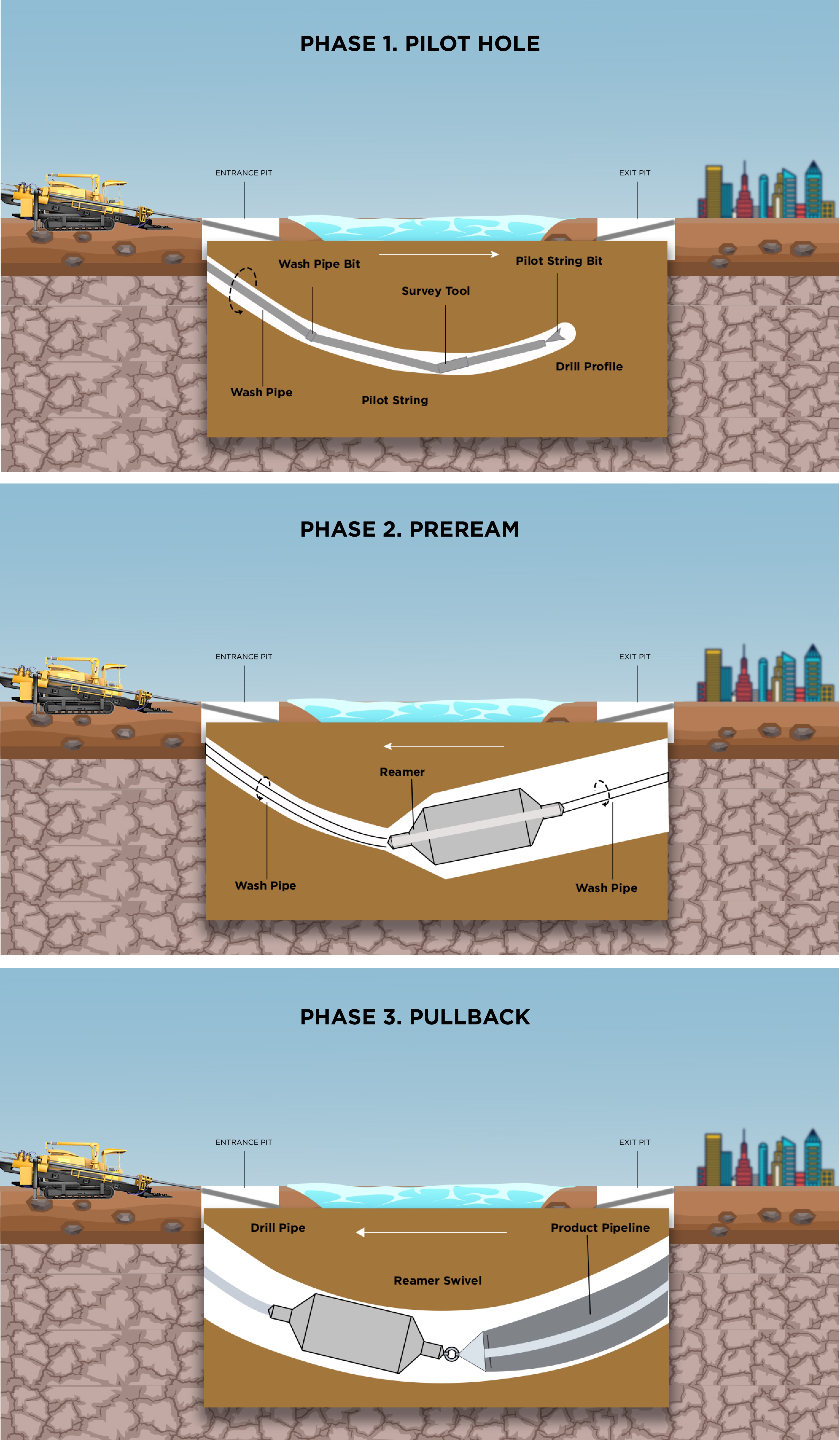

At the starting point, an entrance pit is excavated. This is usually used to manage drilling fluid, a blend of water and bentonite clay which is pumped to the drill bit to clear and flush cuttings and to lubricate the bit and the drill string or drill shaft in some HDD projects. The receiving pit is excavated at the opposite end of the bore path. After planning the bore path to avoid any known obstacles, there are three steps in installation: (1) drill the pilot bore, (2) reaming or back-reaming and (3) installation of the conduit or pipe. The pilot bore is a small diameter hole that traces the preplanned bore path. Once the drill bit comes to the surface at the receiving end the pilot boring is complete. At the receiving end, the bit is replaced by a ream or back-ream. The ream enlarges the pilot bore diameter to about 1.5 times the diameter of the conduit or pipe. Reaming may have to be repeated to achieve the desired diameter for the conduit or pipe being installed.

In the final step, the pipe or conduit is assembled and tested, as necessary, on the surface at the receiving end. The conduit or pipe is attached to the ream with a swivel between them. The swivel prevents any torsional forces developed by the ream from being transferred to the conduit or pipe resulting in the conduit or pipe being pulled back without twists. The finished project includes an underground conduit or pipe with its ends in the entrance and receiving pits.

HDD Rigs: Mini-Midi-Maxi:

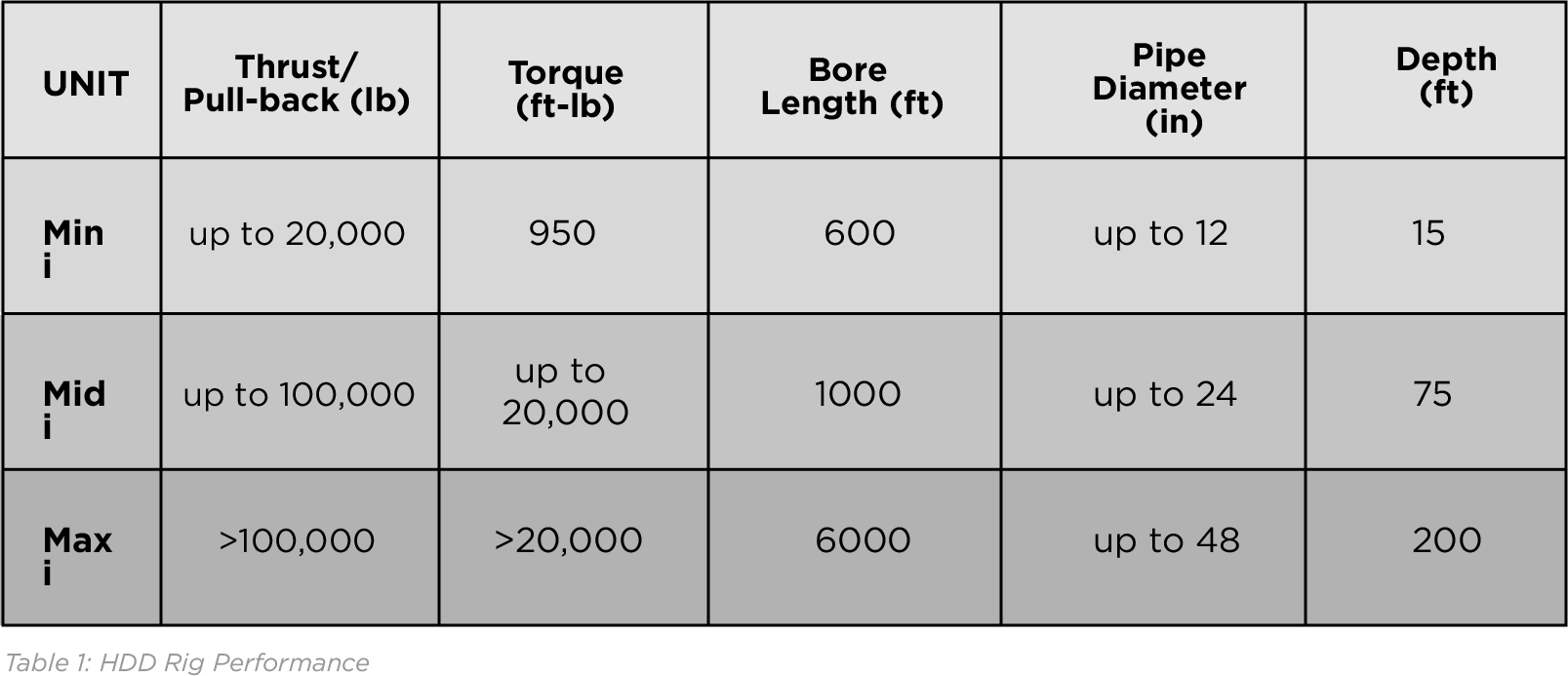

Mini-Midi-Maxi differentiates HDD rigs according to critical operational features, thrust, pull-back and torque. Thrust and pull-back are the forces to push and pull the drill pipe and tools through the bore in both directions. Torque refers to the force on the rotating drill bit or ream.

Although there are not standards to differentiate between mini, midi and maxi rigs, a good rule of thumb can be seen in Table 1.

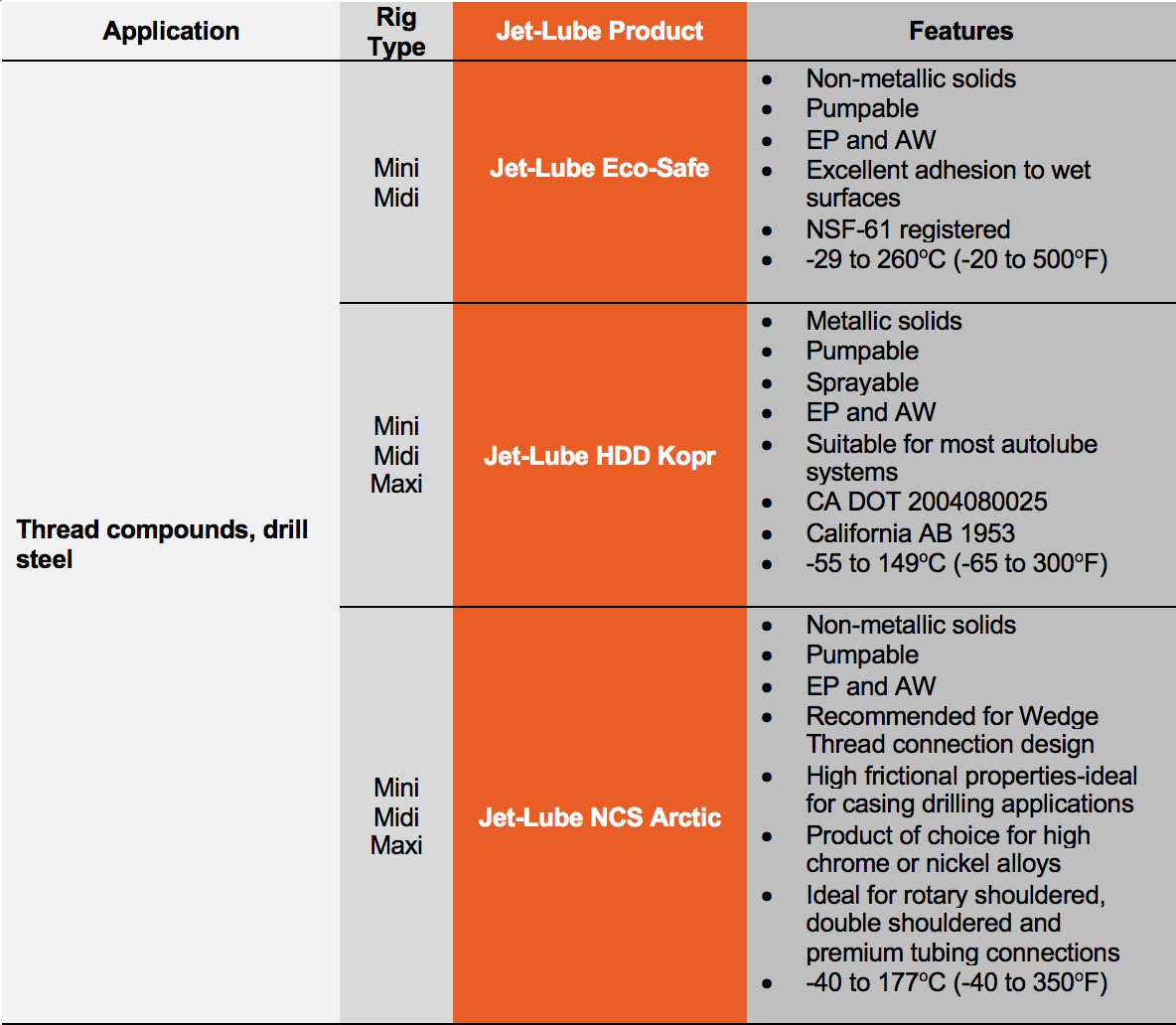

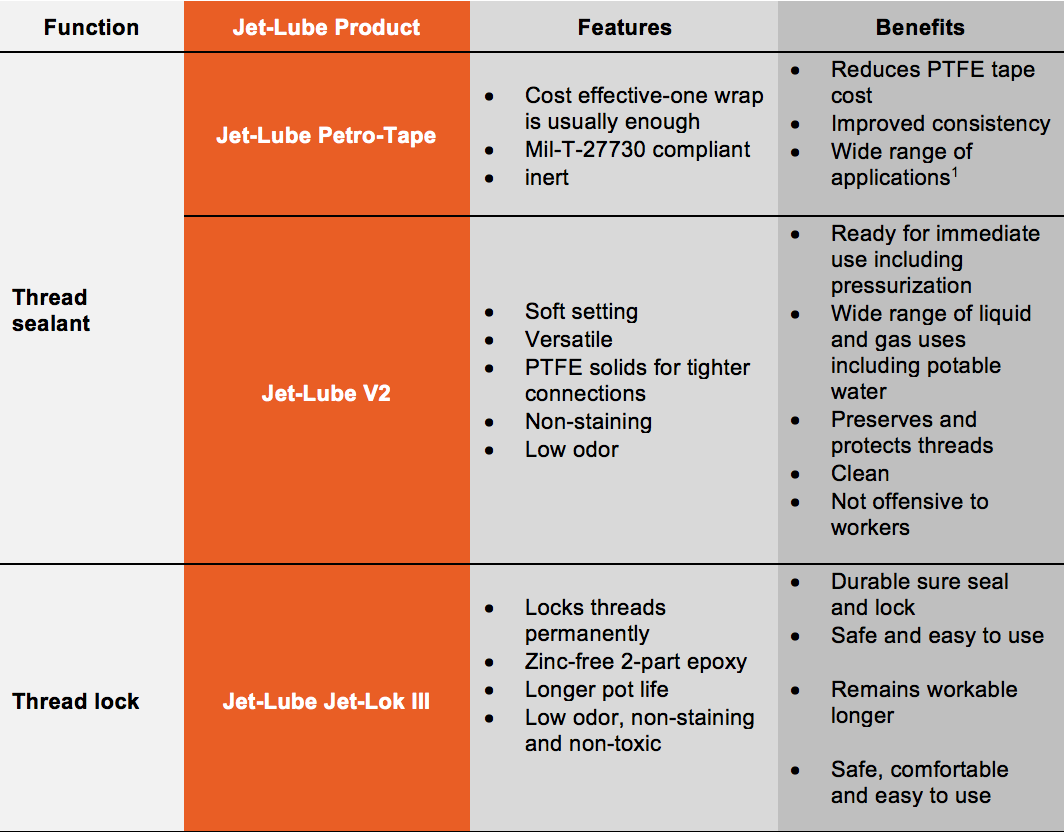

Jet-Lube HDD Product Offering:

There are several opportunities in an HDD operation that Jet-Lube can offer solutions and value for.

Jet-Lube® is an industry leader for thread compounds, thread sealants and thread locking compounds.

1 Jet-Lube Petro-Tape is compatible with the following transport materials: steam, saltwater, air, fuels, refrigerants, acids and alkalis (including sulfuric, hydrochloric, nitric, sodium hydroxide and chromic), solvents (including kerosene, aircraft oils, gasoline, diesel, carbon tetrachloride and cleaning fluids) and gases (including liquid and gaseous oxygen, hydrogen, ammonia, freon, chlorine, propane, natural gas, butane and nitrogen).

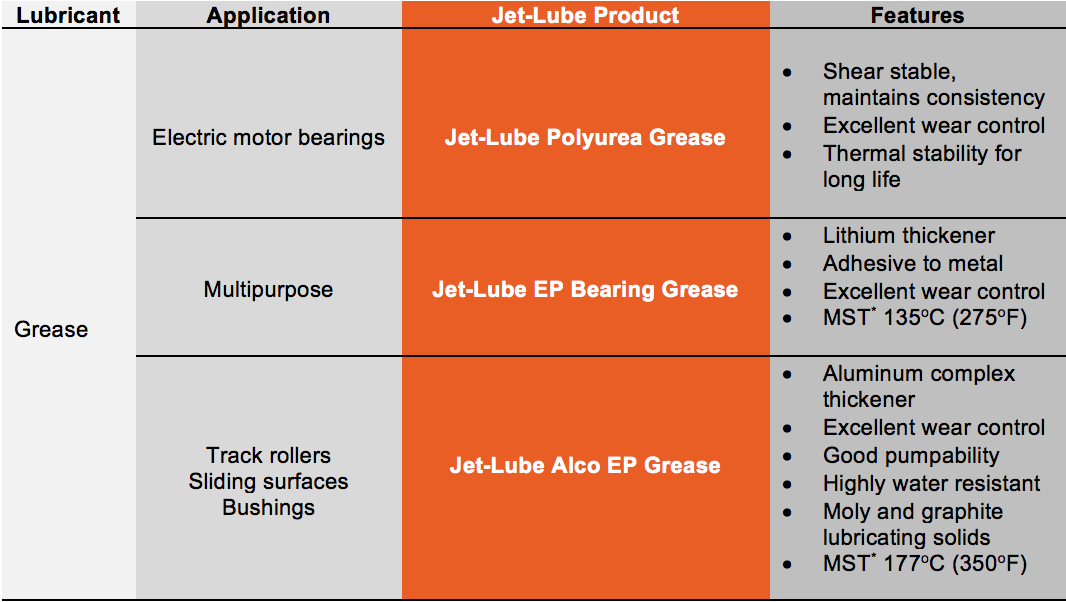

*MST: Maximum Service Temperature

Jet-Lube HDD Toolbox Items:

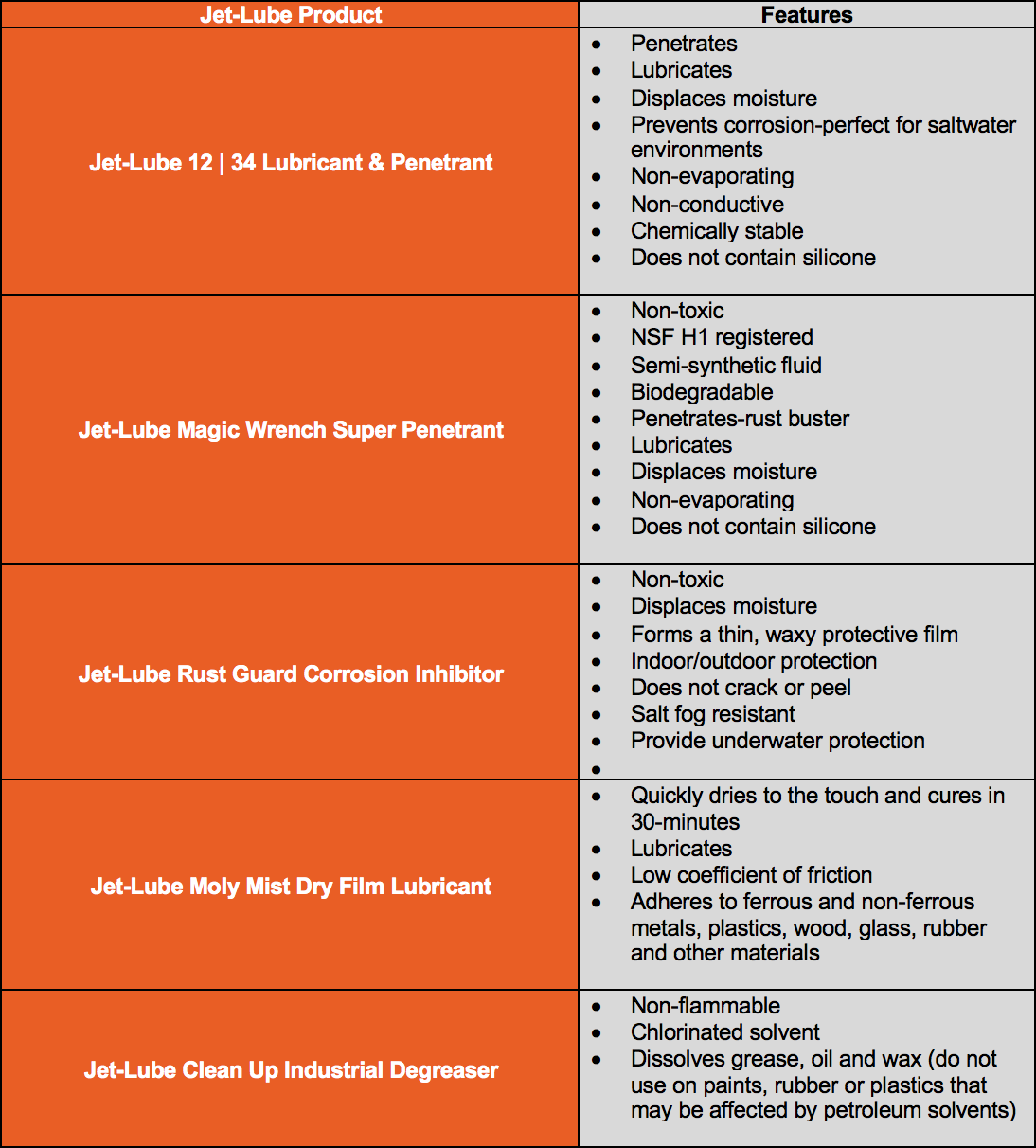

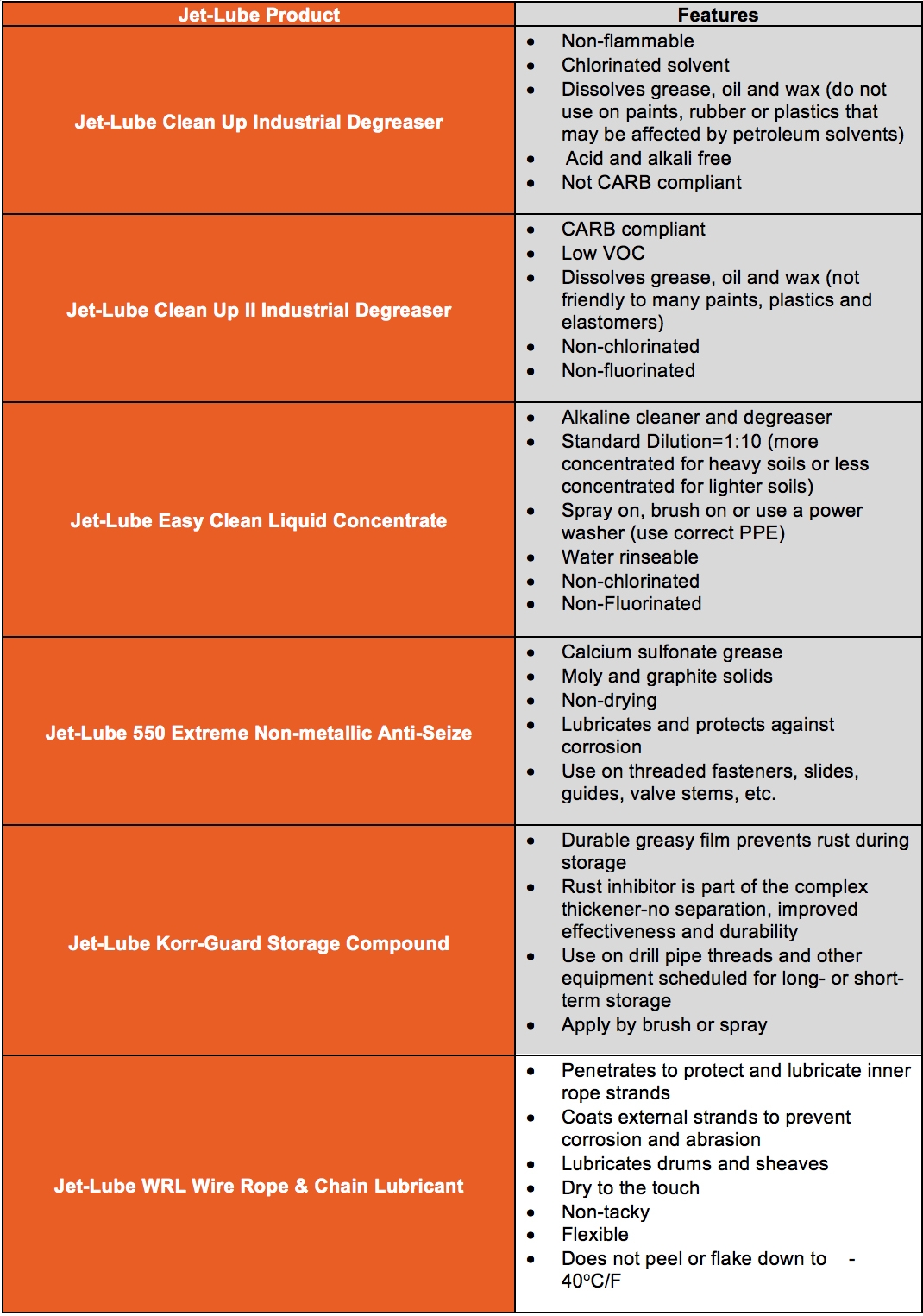

Every maintenance specialist keeps favored general maintenance products in his toolbox or tool chest. Normally these include convenience products, probably the most widely used one being spray penetrant and lubricant. Grab the penetrating oil from your toolbox, spray the bolt you're trying to loosen then grab your wrench and finish the job.

Jet-Lube offers a full range of general maintenance products for fast and easy loosening, lubricating, cleaning and preserving.

Here are a few product suggestions:

If you want to know more, please read our article in April's Issue of Trenchless Technologies.

Pair Jet-Lube HDD Products with Jet-Lube's Sister Brand (Whitmore) Reliability Line - Air Sentry Desiccant Breathers and Oil Safe Lubrication Management Products, oilsafe.com and airsentry.com

Not all Jet-Lube HDD products are mentioned in this article. Check out more here https://www.jetlube.com/indust...

Contact Jet-Lube at sales@jetlube.com / +1 972-771-1000 for product recommendations and information regarding your application and environment conditions.