How does Mold-Pac work?

Posted on 03/30/21 in: Product Knowledge | Technical Knowledge | Mining | General Industry | Manufacturing | Aerospace | Cement | Author: Steve Spiegel

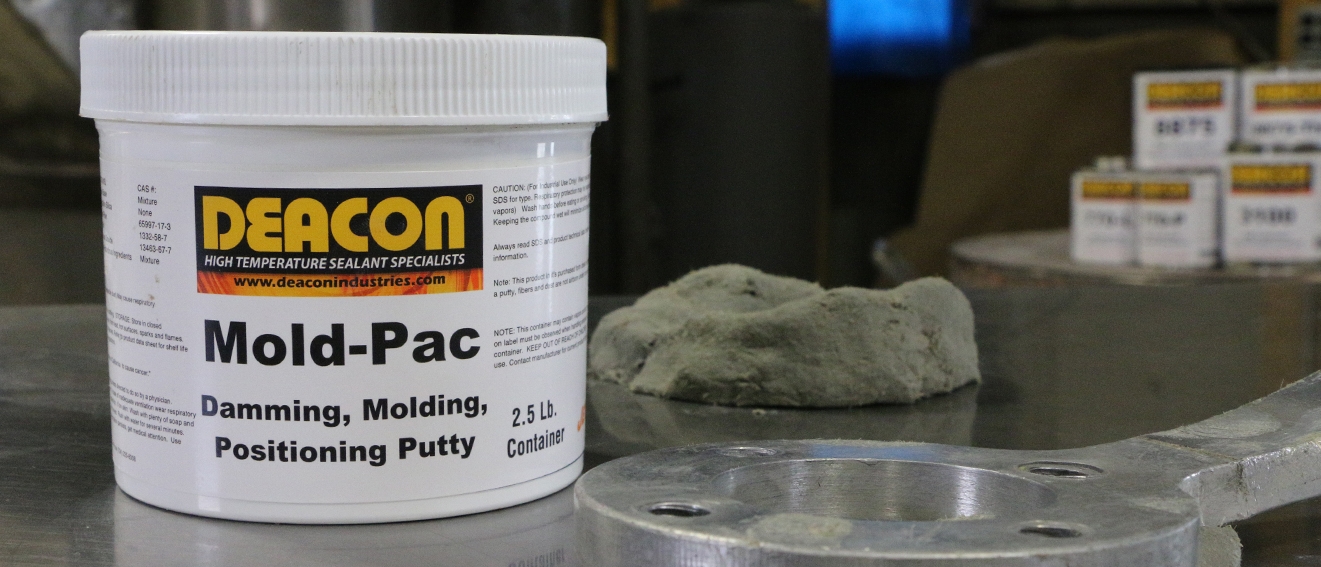

Deacon Mold-Pac is a high-performance damming, molding, and positioning putty designed for use across a very diverse range of industries. It remains flexible (non-hardening), is easily packed in place, asbestos-free, resistant to all weather conditions, and can be quickly removed. In the Mining, Cement, and Crushed Aggregate markets, the product is used to prevent backing compounds (epoxy) from escaping cone/gyratory crushers during a liner change. It's also used in wire rope applications to temporarily hold epoxy resin in place on choker socket assemblies until hardened. For the Manufacturing and Foundry industries, Deacon Mold-Pac is used as a damming / stop-off compound when pouring Babbitt bearings, zinc (Deacon Mold-Pac HD), retaining a pool of dielectric fluid during the EDM cutting process (Deacon Mold-Pac EDM), and various casting operations. In Aerospace and other industries when machining is conducted, Deacon Mold-Pac is used to suppress (absorb) vibration, prevent chatter, and fill in gaps on thin-walled parts, which creates a more efficient process.