Lubricant Failure Mechanisms

Posted on 04/17/20 in: Technical Knowledge | | Author: Michael Holloway

Machines requiring a lubricant film experience a wide range of failure opportunities. Typically, the most common is surface degradation due to a contaminant. There are several types of surface wear mechanisms with the majority due to a particle affecting the surface of a bearing, rolling element, gear face, or pump component.

Abrasive Wear

Abrasive particles enter the space between two moving surfaces, bury themselves in one of the surfaces, and cut material from the opposing surface.

The particles that cause the most damage are those with dimensions equal to and slightly larger than the clearance space. If the particles are too large, they can’t fit into the space, if they are too small, they float right through.

Chain reaction of abrasive wear occurs when particles generated as a result of abrasive wear become work-hardened; they become harder than the parent surface and, if not removed by proper filtration, will re-circulate to cause additional wear. This will continue and result in premature system component failure unless adequate filtration is applied to break the chain.

Erosive Wear

Erosive wear is caused by particles that strike a surface or edge and remove material as they flow over it. It is similar to the erosive wear of water flowing over rocks. This type of wear is found in metering valves where there is high-velocity flow. The impact of particles also causes denting and eventual fatigue of the surface.

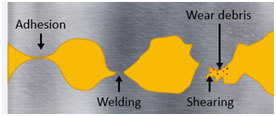

Adhesive Wear

Adhesive wear occurs when excessive load, low speed and/or reductions in fluid viscosity can reduce the lubricant film thickness to a point where metal-to-metal contact occurs. Surface asperities are “cold welded” together and get sheared off.

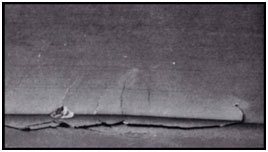

Fatigue

Fatigue is a result of repeated stressing caused by particles trapped by the two moving surfaces. In the beginning, the surfaces are dented and cracks start to form. The cracks spread, and eventually the surface fails, producing a spall.

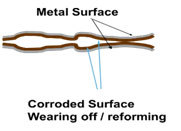

Water Contamination Failure

The most common non-particle contaminant is water. The effects of water are insidious. Failure due to water contamination may be catastrophic, but it may not be immediate. Often the most common result of water contamination is rust. Water has dissolved oxygen which oxidizes the surface of metal. The metal oxides of iron or iron alloys typically do not have the physical integrity as the original state and succumb to failure.

Many failures blamed on lubricants are truly caused by excess water. The following are some of the effects of water on equipment:

- Shorter component life due to rust and corrosion

- Water etching/erosion, hydrogen embrittlement

- Oxidation of bearing babbitt

- Wear caused by loss of oil film or hard water deposits

- Lack of lubrication due to filter blocking or freezing

The effects of water on lubricating oil can be equally harmful:

- Water accelerates oxidation of the oil

- Depletes oxidation inhibitors and demulsifiers

- May cause some additives to precipitate

- Causes ZDDP anti-wear additive to destabilize over 180°F

- Competes with polar additives for metal surfaces

Water etching can be found on bearing surfaces and raceways. It is primarily caused by the generation of hydrogen sulfide and sulfuric acid from water-induced lubricant degradation. Erosion occurs when free water flashes onto hot metal surfaces and causes pitting. Hydrogen embrittlement occurs when water invades microscopic cracks in metal surfaces. Under extreme pressure water decomposes into its components and releases hydrogen. This explosive force the cracks to become wider and deeper, leading to spalling.

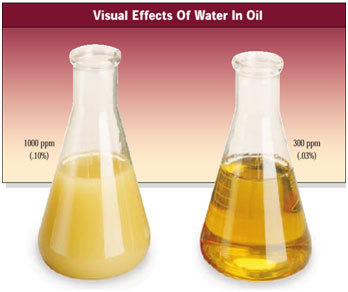

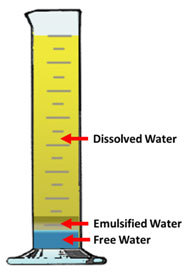

Water can be found in three phases. Most industrial oils will have about 200 ppm dissolved water and are still bright and clear at room temperature.

An exception to this is a phosphate ester, which may contain 1000 ppm dissolved water before it starts to get cloudy. Emulsified water can be more harmful. Since oil and water do not mix, in order to form an emulsion; there must be an emulsifying agent, such as a detergent, and energy. Since it has intimate contact with the oil, it can cause rusting, oxidation and wear. High viscosity fluids form emulsion more readily and permanently than do less viscous fluids.

Logic would say that an oil mixed with water would get thinner, but surprisingly enough, most rich oil/water emulsions have a higher viscosity than either of their components. Free water sinks to the bottom of the sump. It should be removed to prevent it from circulating and causing rust. Free water also promotes the growth of bacteria and fungus.

Controlling water contamination will reduce failure. Actions to take to minimize water contamination:

- Prevent wash down water from entering vents and reservoir covers

- Properly install and seal covers and hatches

- Watch for condensation caused by cold water lines located close to a hot reservoir

- Install secondary seals or v-rings on critical systems

- Install desiccant air breathers or vapor extractors

- Prevent water from entering new oil by storing drums indoors. If they must be stored outdoors, keep them under a shed or tarp, or store them on their sides with the bungs horizontal at the 3 and 9 o’clock positions.

- Tanks should be stainless steel or coated with an oil-resistant paint

Air Related Failure

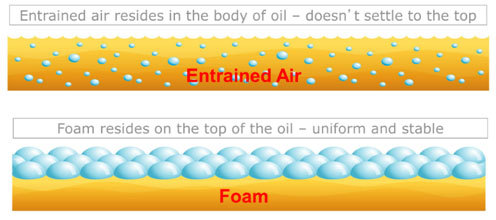

Almost all lubricating oil systems contain some air. Air is found in four phases: free air, dissolved air, entrained air and foam. Free air is trapped in a system, such as an air pocket in a hydraulic line, and may have minimal contact with the fluid. It can contribute to other air problems when lines are not bled properly during equipment start-up and free air is drawn into circulating oils. Dissolved air is not readily drawn out of solution. It becomes a problem when temperatures rise rapidly, or pressures drop. Petroleum oils contain as much as 12% dissolved air.

When a system starts up or when it overheats, this air changes from a dissolved phase into small bubbles. If the bubbles are less than 1 mm in diameter, they remain suspended in the liquid phase of the oil, causing air entrainment. Air entrainment is a small amount of air in the form of extremely small bubbles dispersed throughout the bulk of the oil. Air entrainment is treated differently than foam and is most often a completely separate problem. Some of the potential effects of air entrainment include:

- Pump cavitation

- Spongy, erratic operation of hydraulics

- Loss of precision control; vibrations

- Oil oxidation

- Component wear due to reduced lubricant viscosity

- Equipment shut down when low oil pressure switches trip

- “Micro-dieseling” due to ignition of the bubble sheath at the high temperatures generated by compressed air bubbles

- Safety problems in turbines if overspeed devices do not react quickly enough

- Loss of head in centrifugal pumps

Air contamination can bring about foam which is a collection of closely packed bubbles surrounded by a thin film of oil that collects on the surface of the oil. It is generally cosmetic, but it must be treated if it makes oil level control impossible, if it spills onto the floor to create a safety or housekeeping hazard, causes airlocks at high points, or is so extreme that equipment is lubricated with foam.

Particulates act as seeds on which bubbles grow. Anti-foam additives may also be attracted to their surface, reducing their effectiveness in the bulk oil. Cement dust can cause foaming. Air can do the following:

- Accelerates oxidation

- Shortens oil lifecycle

- Create sludge

- Creates cavitation wear

If air is dispersed throughout the fluid and clears very slowly, and the system is relatively stagnant, the air entrainment is probably caused by silicone contamination. Check seals, gaskets and other possible sources of silicone. If the system is turbulent, watch for an air leak on the suction side of a high-pressure oil pump or for working elements that may churn the air into tiny bubbles. If the root cause cannot be corrected, it may make sense to add an after-market anti-foam in this case.

Cavitation occurs when air or a water vapor bubble experiences an implosion on a surface at a low-pressure (vacuum) zone. The air bubbles expand and collapse as they pass through pressure change zones. This occurs in mechanical systems where the fluid pressures change by design or flaw. Systems that can experience cavitation include engines, plain bearings and other sliding surfaces, as well as pump inlets. In order to control cavitation, it is recommended to:

- Control air entrainment

- Control water introduction

- Prevent presence of foam or air bubbles

- Maintain pump shaft seals

- Eliminate any system flow constrictions

- Decrease oil viscosity to improve flow conditions

- Maintain corrosion control additive health

Contamination is responsible for the majority of failure opportunities in a lubricated system. A proven practice to reduce water and particulate contamination is through the use of filters and reservoir air breathers.

Summary

It has been determined that more than 75% of all machine wear-related failures were due to particulate contaminants. Frequently, the greatest cost of equipment failure is not the component replacement cost, but the labor production downtime. Most particles start off as dirt that becomes airborne, then find its way into lubricant and fuel reservoirs, and is later transported to bearings, bushings, seals, valves, and other machine components.

There they become key ingredients in abrasion, erosion, and fatigue failures. The contaminants also cause lubricant degradation, shortening the life of the lubricant and decreasing its ability to lubricate. With machine clearances measured in thousandths of an inch, it does not take much contamination to affect bearings and other sensitive components. Even particles of 10 microns or smaller can disrupt the lubricant film and cause a great amount of wear.

Taglines for Lubrication Failure Modes

- Contamination is responsible for the majority of failure opportunities in a lubricated system. Learn about the various sources of contamination and their impact on your equipment reliability.

- Contamination can be internally generated or from external sources. Understanding how contaminants develop or enter your system will help reduce the dangerous effects. Learn about the various sources of contamination and their impact on your equipment reliability.

- Abrasive particles enter the space between two moving surfaces, bury themselves in one of the surfaces, and cut material from the opposing surface. Learn about the various sources of abrasive wear and the impact on your equipment reliability.

- Erosive wear is caused by particles that strike a surface or edge and remove material as they flow over it. It is similar to the erosive wear of water flowing over rocks. Learn about the various sources of erosive wear and the impact on your equipment reliability.

- Adhesive wear occurs when excessive load, low speed and/or reductions in fluid viscosity can reduce the lubricant film thickness to a point where metal-to-metal contact occurs. Learn about the various sources of adhesive wear and the impact on your equipment reliability.

- Fatigue is a result of repeated stressing caused by particles trapped by the two moving surfaces. In the beginning, the surfaces are dented and cracks start to form. Learn about the various sources of fatigue wear and the impact on your equipment reliability.

- The most common non-particle contaminant is water. The effects of water are insidious. Failure due to water contamination may be catastrophic, but it may not be immediate. Learn about the various sources of water and the impact on your equipment reliability.

- Water can be found in three phases. Most industrial oils will have about 200 ppm dissolved water and are still bright and clear at room temperature. Learn about the various phases of water and the impact on your equipment reliability.

- Water can bring about more than just rust. Learn how water has an influence on the formation of foam as well as reacting with the additive chemistry.

- Almost all lubricating oil systems contain some air. Air is found in four phases: free air, dissolved air, entrained air and foam. Learn about the various phases of air in your oil and the impact on your equipment reliability.