Mastering Industrial Lubricant Handling: A Comprehensive Guide to Optimize Performance and Protect Assets

Posted on 07/20/23 in: Technical Knowledge | Industry News | Agriculture | Food & Beverage | Oil & Gas | Mining | General Industry | Plant Maintenance

Effective storage, transfer, identification, and protection protocols for industrial lubricants are crucial for maintaining their quality and performance. Many facilities overlook the dangers associated with improper lubricant handling, which can result in equipment reliability issues and shortened lifecycles. In this comprehensive guide, we will delve into the essential practices that will empower you to optimize lubricant performance, prolong their shelf life, and minimize the risk of contamination or degradation.

The Significance of Proper Storage Conditions

The storage environment significantly impacts lubricant quality and longevity. We will discuss the importance of a designated lube storage room, its key features, and how it ensures functional, safe, and expandable storage. Additionally, we will explore the role of limited access, visible landing areas, proper safety devices, and effective inventory tracking systems in maintaining optimal storage conditions.

Efficient Bulk Storage and Dispensing Systems

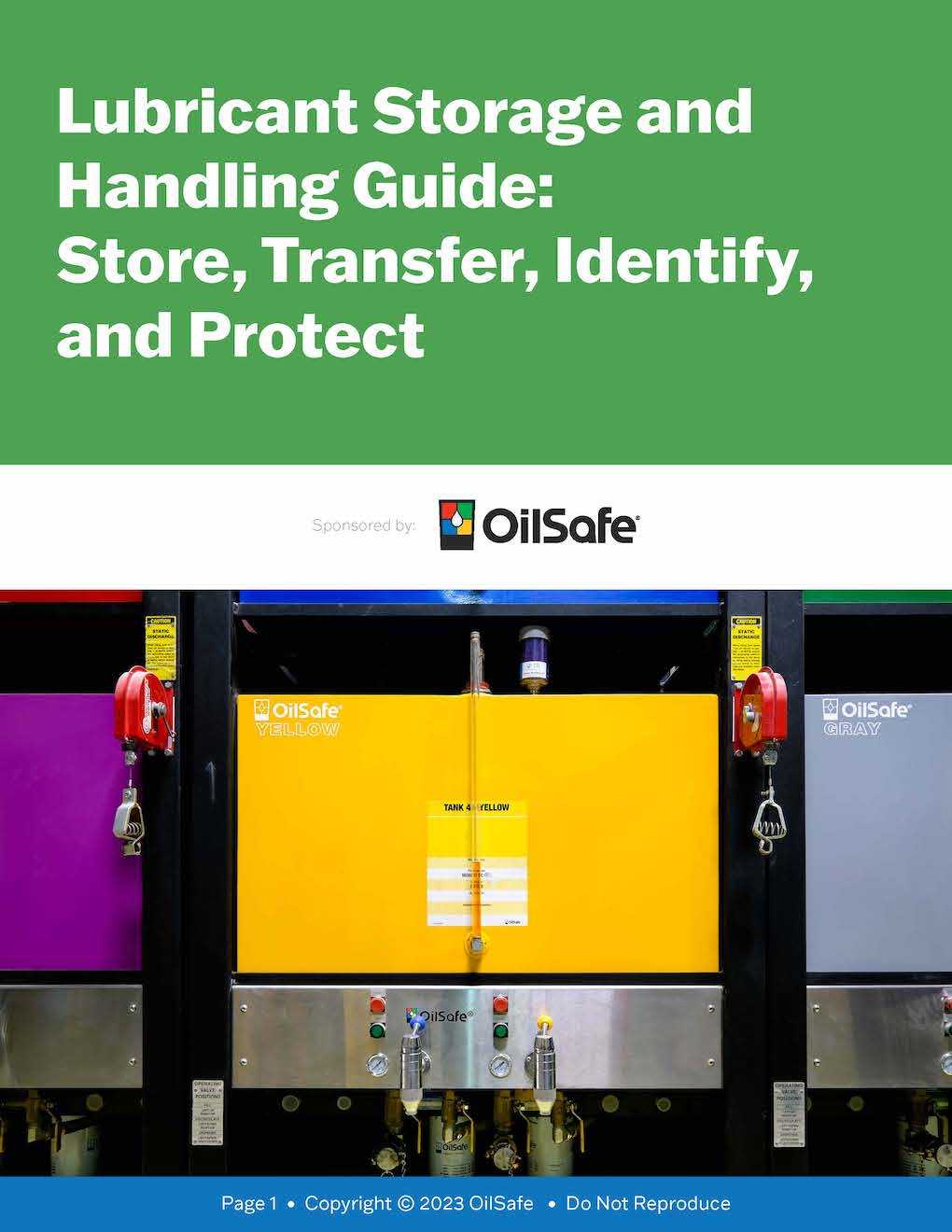

Bulk storage systems are commonly used in industries that require large quantities of lubricants. We will dive into the design features of bulk storage tanks, including material selection and compatibility considerations. Furthermore, we will explore the use of sight gauges, breathers, filtration and conditioning equipment, and overfill protection devices, highlighting their roles in ensuring clean, controlled, and spill-free lubricant handling.

Seamless Oil Transfer Techniques

Mastering the art of transferring lubricants is essential for preventing spills and contamination. We will discuss the various oil transfer equipment, such as oil drums and barrels, extension hoses, quick connects, and pumps. Understanding their functionalities and choosing the appropriate equipment for specific transfer needs will enable you to execute efficient and controlled oil transfers.

Precision Identification and Labeling

Clear identification and labeling practices are essential to prevent cross-contamination and confusion. We will explore the significance of segregating lubricants based on type and the use of color-coding and symbol schemes. By implementing proper identification and labeling techniques, you can ensure accurate lubricant matching and eliminate the risk of costly mix-ups.

Proper handling of industrial lubricants is crucial for maximizing equipment performance, extending lifecycles, and protecting valuable assets. By following the techniques outlined in this comprehensive guide, you can optimize lubricant efficiency, minimize the risk of contamination or degradation, and enhance overall operational reliability. Don't compromise on the quality and performance of your lubricants—take charge of your maintenance practices and download our guide today.

Remember, effective storage, transfer, identification, and protection of industrial lubricants are the keys to a seamless and reliable operation. Equip yourself with the knowledge and strategies provided in this guide, and embark on a journey of enhanced performance and asset protection